Kingda Jar Rolling Ball Mill

Kingda Lab Roller Ball Mill

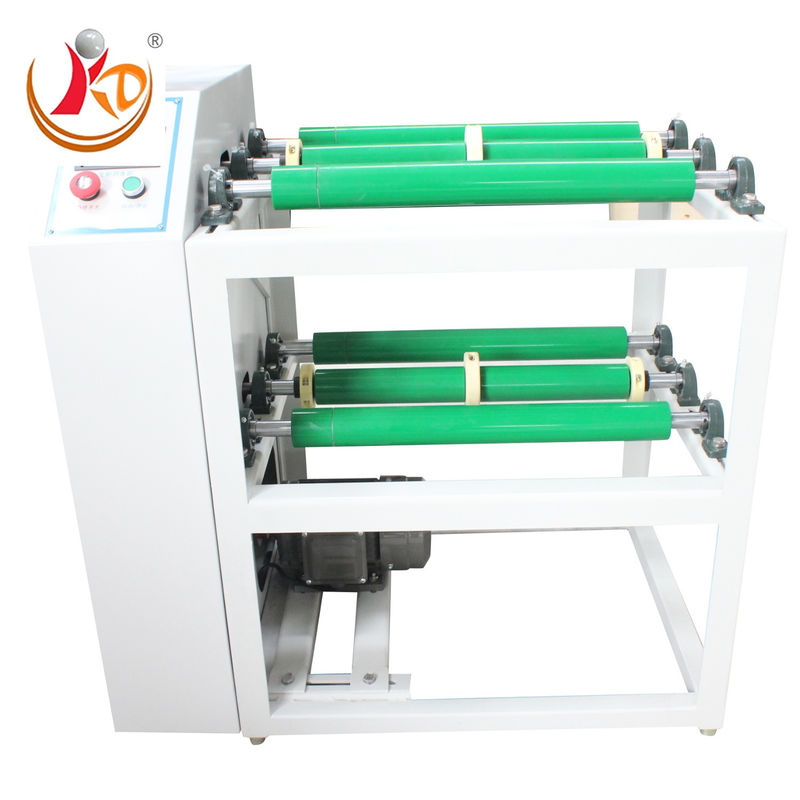

Product Overview

01. Grinding Mill Jar

02. Frequency Conversion Control

03. Two Rollers

Key Features and Components

- Rollers: Two or more adjustable rollers support and rotate jars, accommodating different sizes for optimal grinding

- Jars: Various sizes and materials available to suit different applications and materials

- Grinding Media: Balls or rods of varying sizes and types to achieve desired particle size

- Motor and Drive System: Powerful motor with adjustable rotation speed for precise process control

- Controls and Safety: Adjustable speed, timer functions, and safety interlocks for secure operation

Working Principle

During operation, grinding media and materials inside the cylinder rotate to a specific height and then descend under gravity from the inner walls. Material crushing occurs through a combination of impact, friction, and shearing forces from rolling and sliding movements. This optimized process enhances efficiency while ensuring smooth, effortless operation.

Technical Specifications

| Category |

Model No. |

Power Supply |

Rotate Speed |

Max Load Per Jar |

Dimensions & Net Weight |

| 2 Work Positions |

GQM-2-5 |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*480*685mm 59KGS |

| GQM-2-15 |

220V-50Hz or 60Hz/1.1kw |

40-365 rpm |

80KGS |

1130*550*690mm 80KGS |

| GQM-2-20 |

220V-50Hz or 60Hz/1.5kw |

40-340 rpm |

120KGS |

1350*650*690mm 92KGS |

| 4 Work Positions |

GQM-4-5 Single layer |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*660*690mm 70KGS |

| GQM-4-5 Double layer |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*480*870mm 92KGS |

| GQM-4-15 |

220V-50Hz or 60Hz/1.5kw |

40-365 rpm |

80KGS |

1130*800*690mm 95KGS |

| GQM-4-20 |

380V-50Hz or 60Hz/2.2kw |

40-340 rpm |

120KGS |

1350*820*690mm 122KGS |

| 8 Work Positions |

GQM-8-5 |

220V-50Hz or 60Hz/1.5kw |

50-410 rpm |

35KGS |

950*660*960mm 106KGS |

|

| GQM-8-15 |

380V-50Hz or 60Hz/2.2kw |

40-365 rpm |

80KGS |

1130*800*960mm 152KGS |

|

Advanced Features

- Simultaneous grinding of multiple sample materials

- Both intermittent and continuous operation modes available

- Adjustable timing to meet specific requirements

Grinding Pots & Balls Accessories

Available grinding jars in full sizes: Zirconia ball mill jar, alumina ball mill jar, Tungsten ball mill, hard metal mill jar and more.

Choose The Right Jar For Your Material

| Materials & Requirements |

Recommended Solutions |

| Soil materials and other materials not allowing impurity contamination |

Agate mill jar |

| Metal or nonmetal materials not allowing impurity contamination |

Zirconium mill jar |

| High hardness materials like diamond, tungsten carbide |

Tungsten carbide mill jar |

| Strong acid & alkali materials, or materials under high temperature |

PTFE mill jar |

| Iron ore materials or materials with low impurity sensitivity |

304 stainless steel mill jar |

| Pigment or materials with later processing under high temperature |

Nylon mill jar |

| Aluminum materials like ceramic glaze |

Corundum mill jar |

| Electronic materials like lithium battery |

Polyurethane mill jar |

| Description of Roll Mill Jars |

Available Specifications |

| Normal ceramic roll mill jar |

From 1.0L to 15L |

| 304 Stainless steel roll mill jar |

From 0.5L to 20L |

| Corundum roll mill jar |

From 0.5L to 10L |

| Nylon roll mill jar |

From 0.5L to 20L |

| Polyurethane roll mill jar |

From 0.5L to 20L |

| PTFE/Teflon roll mill jar |

From 0.5L to 20L |

| Tungsten carbide roll mill jar |

From 250ml to 3L |

| Roll jacket (Stainless steel) |

0.5L to 3L |

| 316L Stainless steel roll mill jar |

Customized |

Package & Shipping

Package Type: PE Form + Cartons / Wooden cases; Can be dispatched according to customer's requirement

Port: Shanghai Port, Guangzhou Port, Tianjin Port, Qingdao port.

Delivery Time: Within 3-7 working days from the date of payment receipt

Manufacturing Facility

Frequently Asked Questions

Q: What are the roll mill jars available in your products?

A: Our available roll mill jars are alumina / zirconia ceramic, nylon, stainless steel, tungsten carbide, PTFE, polyurethane and more.

Q: What is your terms of delivery?

A: FOB, CFR, CIF.

Q: Can you accept small quantity sample order before production?

A: Yes, we can offer sample for your testing first before production, but the customers have to pay the courier cost.

Q: What is your production time?

A: Generally, it will take 3-15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q: What is your terms of payment?

A: T/T 30% as deposit, 70% balance against the copy of original B/L. Or 100% L/C at sight. We'll show you the photos of the products and the copy of original B/L before you pay the balance.

Customer Service Commitment

- Custom grinding balls production according to your specific needs

- Comprehensive testing of all goods before delivery

- Respectful business relationships built on trust and friendship

- Prompt customer support with 2-hour response time

About Kingda Ceramic Technology

- HUNAN KINGDA CERAMIC TECHNOLOGY CO.,LTD specializes in manufacturing Grinding Media Balls, Grinding Jars, Zirconium Dioxide, and Zirconia structures

- "Quality Is in the First Position forever" - trusted by prestigious institutions including University of Oxford, Loughborough University, Peking University, and Tsinghua University

- Commitment to providing high quality grinding products and exceptional services

- Established reputation for mutual benefit and sustainability with business partners

- Dedicated to advancing ceramic technology with passion and expertise

Related Products

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!