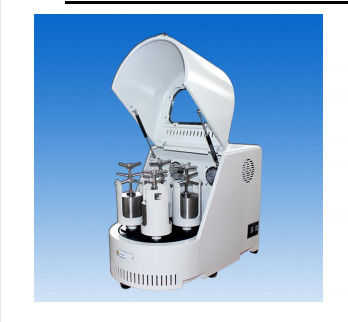

0.4L Ceramic Ball Mill 220V Desktop Laboratory Grinding Equipment

Product Overview

- The Vertical Planetary Ball Mill is an essential device for high-tech materials mixing, fine grinding, sample preparation, new product development, and small batch production

- With compact design, high efficiency, low noise, and versatile features, this mill is ideal for research institutions, universities, and enterprise laboratories requiring precision in sample preparation

- Features four ball grinding tanks installed on one turnplate that creates planetary movements for high-speed grinding and mixing

- Capable of processing various materials and granularities using dry or wet methods, achieving minimum particle sizes down to 0.1 micron

- Widely used in Geology, Mining, Metallurgy, Electronics, Construction Materials, Ceramics, Chemical Engineering, Light Industry, Medicine, and Environmental Protection

- Designed with comprehensive safety features and stable 220V power supply performance

Applications

- Materials Research and Development: Crucial for mixing, fine grinding, and new product development of high-tech materials, enabling rapid production of samples with high purity and precise particle size

- Laboratory Sample Preparation: Ideal for universities, research institutions, and enterprise laboratories, capable of processing four samples simultaneously to enhance experimental efficiency

Technical Specifications

| Drive Mode |

gear drive / belt drive |

| Operation Mode |

2 / 4 grinding tanks working together |

| Maximum Loading Capacity |

2/3 of the capacity of milling tank |

| Feeding Granularity |

soil material ≤10mm, other materials ≤3mm |

| Output Granularity |

Minimum 0.1um |

| Rotational Speed Ratio |

1:2 (0.4L,2L,4L); 1:1.5(12L,20L) |

| Rotation Speed |

0.4L: 0~600 rounds/min; 2L: 0~580 rounds/min; 4L: 0~530 rounds/min; 20L: 0-280 rounds/min |

| Speed Regulation Mode |

Variable-frequency control and program-control stepless speed regulation; manual or automatic timing; forward or reverse rotation |

| Max. Continuous Operating Time (full-load) |

72 hours |

Planetary Ball Mill Models

| Model |

Specification |

Capacity Range |

Quantity |

| KD-XQM-0.4L |

0.4L |

50-100ml |

4 mill tanks |

| KD-XQM-1L |

1L |

50-250ml |

4 mill tanks |

| KD-XQM-2L |

2L |

560-500ml |

4 mill tanks |

| KD-XQM-4L |

4L |

50-1000ml |

4 mill tanks |

| KD-XQM-8L |

8L |

0.5-2L |

4 mill tanks |

| KD-XQM-12L |

12L |

1-3L |

4 mill tanks |

| KD-XQM-16L |

16L |

1-4L |

4 mill tanks |

Key Features

- Stable gear transmission ensures consistent and repeatable experimental results

- Planetary movement principle delivers high speed, energy efficiency, and fine particle size reduction

- Simultaneous processing of four different powder samples

- Frequency converter control with under-voltage and over-current protection

- Programmable operation modes including timing, directional control, and rotation patterns

- Low center of gravity, stable performance, compact structure, and easy operation

- Integrated safety switch prevents operation when safety cover is open

Packaging & Shipping

Packaging Type: PE Form + Cartons / Wooden cases; Custom packaging available

Port: Shanghai Port, Guangzhou Port, Tianjin Port, Qingdao port

Delivery Time: Within 3-7 working days from payment receipt

Manufacturing Facility

Frequently Asked Questions

Q: What is the size in your products?

A: The minimum type is 0.4L planetary ball mill Model XQM-0.4A (53×30×34cm, 26kg). Models available from 0.2L to 100L capacity.

Q: What is your terms of delivery?

A: FOB, CFR, CIF.

Q: Can you accept small quantity sample order before production?

A: Yes, samples available for testing with customer covering courier costs.

Q: What is your production time?

A: Generally 3-7 days after receiving advance payment, depending on order specifics.

Q: What is your terms of payment?

A: T/T 30% deposit, 70% balance against B/L copy, or 100% L/C at sight.

Q: What is the working principle of planetary ball mill?

A: Working principle of planetary ball mill

Customer Service

- Custom grinding balls available according to specifications

- Comprehensive pre-delivery testing of all goods

- Dedicated customer support with 12-hour response guarantee

About Kingda Ceramic Technology

- Manufacturer of Grinding Media Balls, Grinding Jars, Zirconium Dioxide, and Zirconia structures

- Committed to quality with high reputation among domestic and international customers including University of Oxford, Loughborough University, Peking University, and Tsinghua University

- Dedicated to providing high-quality grinding products and exceptional services

- Focus on mutual benefit and sustainability in business partnerships

Related Products

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!