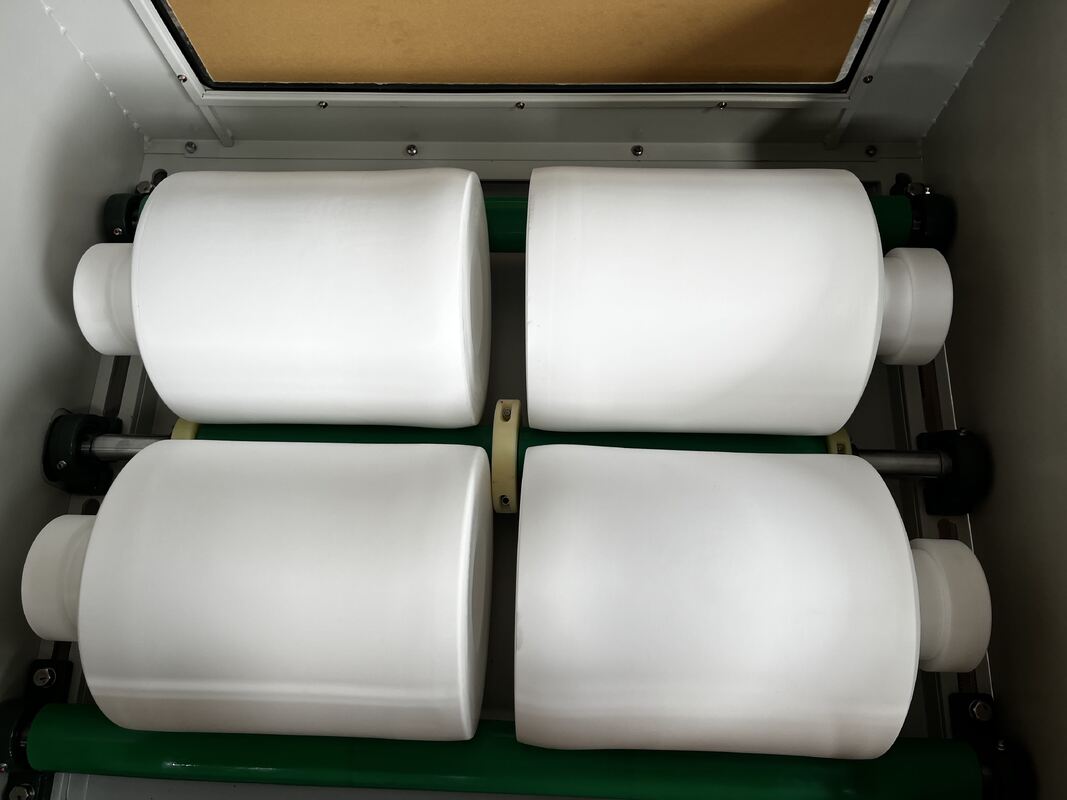

Powder Grinding Jar Mill with Multiple Jar Capacity Options

In scientific research and experimentation, precision and efficiency in laboratory equipment are paramount. The Lab Jar Roller Mill Machine represents a significant advancement in materials science and sample preparation technology.

This robust machine features a series of rotating jars mounted on a horizontal roller. Constructed from high-quality materials including stainless steel and ceramic, these precisely aligned jars ensure efficient milling. The roller mechanism creates both rotational and lateral movement, producing a cascading motion that facilitates effective grinding and mixing.

The Lab Jar Roller Mill Machine offers exceptional versatility, accommodating diverse sample sizes and types across multiple research applications. Whether pulverizing solid materials, blending powders, dispersing pigments, or creating homogeneous mixtures, this equipment provides precise control over particle size reduction and material blending for reproducible, accurate results.

Working Principle

The grinding process begins as media and materials within the cylinder rotate to a predetermined height, then descend from the tube walls under gravity. Material crushing occurs through a combination of impact, friction, and shearing forces from rolling and sliding movements. This optimized procedure enhances efficiency while ensuring smooth, effortless operation.

Technical Specifications

| Category |

Model No. |

Power Supply |

Rotate Speed |

Max Load Per Jar |

Dimensions & Net Weight |

| 2 Work Positions |

GQM-2-5 |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*480*685mm 59KGS |

| GQM-2-15 |

220V-50Hz or 60Hz/1.1kw |

40-365 rpm |

80KGS |

1130*550*690mm 80KGS |

| GQM-2-20 |

220V-50Hz or 60Hz/1.5kw |

40-340 rpm |

120KGS |

1350*650*690mm 92KGS |

| 4 Work Positions |

GQM-4-5 Single layer |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*660*690mm 70KGS |

| GQM-4-5 Double layer |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*480*870mm 92KGS |

| GQM-4-15 |

220V-50Hz or 60Hz/1.5kw |

40-365 rpm |

80KGS |

1130*800*690mm 95KGS |

| GQM-4-20 |

380V-50Hz or 60Hz/2.2kw |

40-340 rpm |

120KGS |

1350*820*690mm 122KGS |

| 8 Work Positions |

GQM-8-5 |

220V-50Hz or 60Hz/1.5kw |

50-410 rpm |

35KGS |

950*660*960mm 106KGS |

| GQM-8-15 |

380V-50Hz or 60Hz/2.2kw |

40-365 rpm |

80KGS |

1130*800*960mm 152KGS |

Key Features

- Simultaneous grinding of multiple sample materials

- Both intermittent and continuous operation modes available

- Adjustable timing to meet specific requirements

Grinding Pots & Balls Accessories

Available grinding jars in various materials:

- Zirconia ball mill jar

- Alumina ball mill jar

- Agate ball mill jar

- Tungsten ball mill jar

- Hard metal mill jar

Package & Shipping

Package Type: PE Form + Cartons / Wooden cases; Custom packaging available

Port: Shanghai Port, Guangzhou Port, Tianjin Port, Qingdao port

Delivery Time: Within 3-7 working days from payment receipt

Manufacturing Facility

Frequently Asked Questions

What roll mill jars are available in your products?

Our available roll mill jars include alumina, zirconia ceramic, nylon, stainless steel, tungsten carbide, PTFE, polyurethane, and more.

What are your terms of delivery?

FOB, CFR, CIF.

Can you accept small quantity sample orders before production?

Yes, we can provide samples for testing before production. Customers are responsible for courier costs.

What is your production time?

Typically 3-15 days after receiving advance payment. Specific delivery time depends on items and order quantity.

What are your payment terms?

T/T 30% deposit, 70% balance against original B/L copy, or 100% L/C at sight. We provide product photos and B/L copy before balance payment.

Our Service Commitment

- Custom grinding balls production available

- Comprehensive pre-delivery testing of all goods

- Customer-focused business relationships

- Prompt response within 2 hours for all inquiries

About Kingda Ceramic Technology

HUNAN KINGDA CERAMIC TECHNOLOGY CO.,LTD specializes in manufacturing Grinding Media Balls, Grinding Jars, Zirconium Dioxide, and Zirconia structures.

Our commitment to "Quality Is in the First Position forever" has earned us high reputation and recognition from prestigious institutions including University of Oxford, Loughborough University, Peking University, and Tsinghua University.

We are dedicated to providing high-quality grinding products and exceptional services to customers worldwide, fostering mutual benefit and sustainability through technological excellence.

Related Products

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!