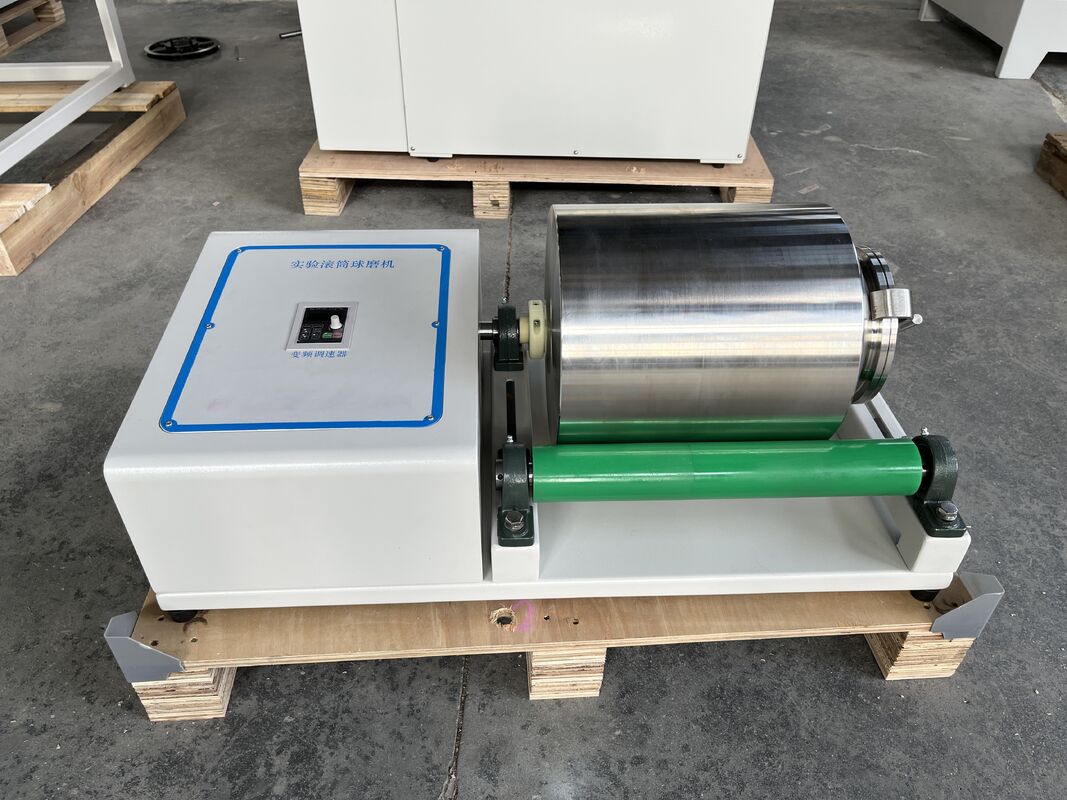

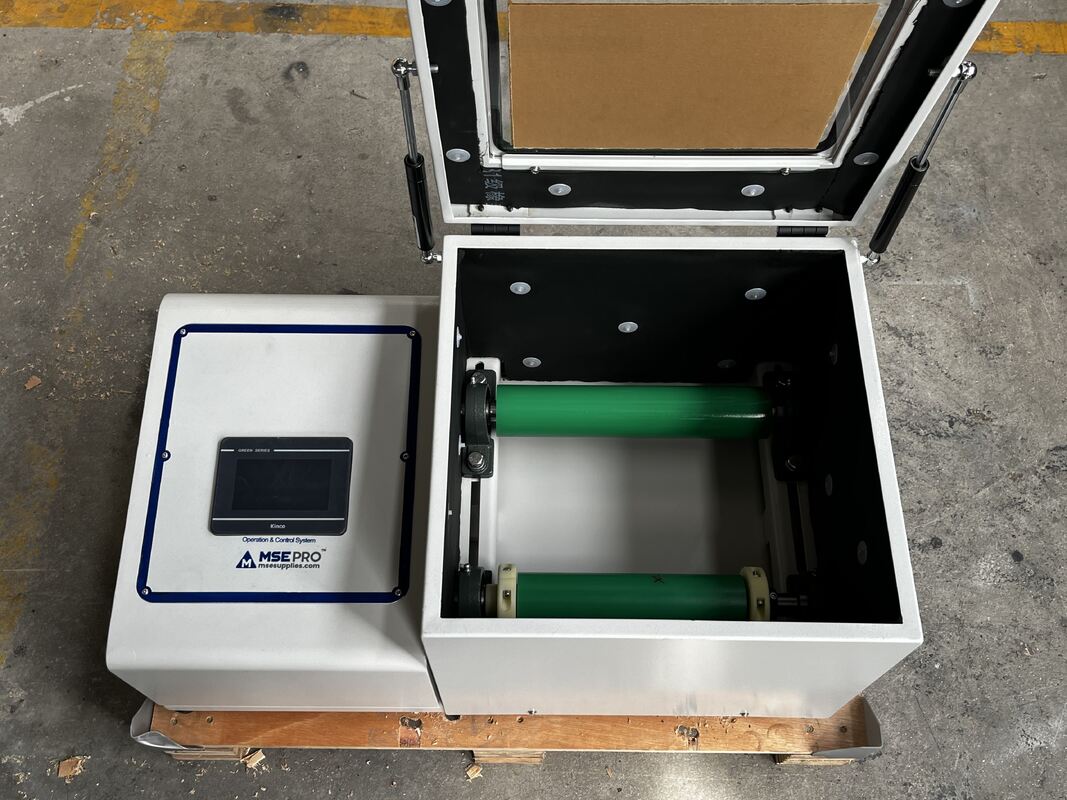

Lab Roller Mill Compact Jar Grinding Equipment for Dry and Wet Milling

Product Applications

- Materials Science and Research: Grind, blend, and homogenize ceramics, glasses, metals, polymers, composites, and nanoparticles for material property studies and particle size analysis.

- Pharmaceutical Development: Reduce particle size, enhance drug dissolution rates, improve bioavailability, and achieve uniform mixing of APIs with excipients.

- Chemical Engineering: Produce fine powders, prepare homogeneous mixtures, and optimize reaction kinetics through efficient particle size reduction.

- Paints, Pigments, and Coatings: Disperse and blend pigments, dyes, and additives for consistent coloration and enhanced coating properties.

- Food and Beverage Industry: Achieve particle size reduction, ingredient blending, and mixture homogenization for consistent quality and texture.

Geological and Environmental Sciences

Grind and prepare geological samples, soils, sediments, and minerals for analysis and characterization studies.

Quality Control and Testing

Assess particle size distributions, evaluate material properties, and verify product performance across various industries.

Working Principle

During operation, grinding media and cylinder materials rotate to a predetermined height and descend from the tube wall under gravity. Material crushing occurs through impact, friction, and shearing from rolling and sliding motions, ensuring efficient operation with minimal time and labor.

Technical Specifications

Technical Parameters of Roll Ball Mill

| Category |

Dimensions/Weight (mm/kgs) |

Model No. |

Motor Power (kW) |

Voltage |

Rotate Speed (rpm) |

| Lab Model |

730*415*260/35 |

QM-5 |

0.37 |

220V-50Hz/60Hz |

60-570 |

|

845*435*270/43 |

QM-15 |

0.75 |

220V-50Hz/60Hz |

60-570 |

Key Features

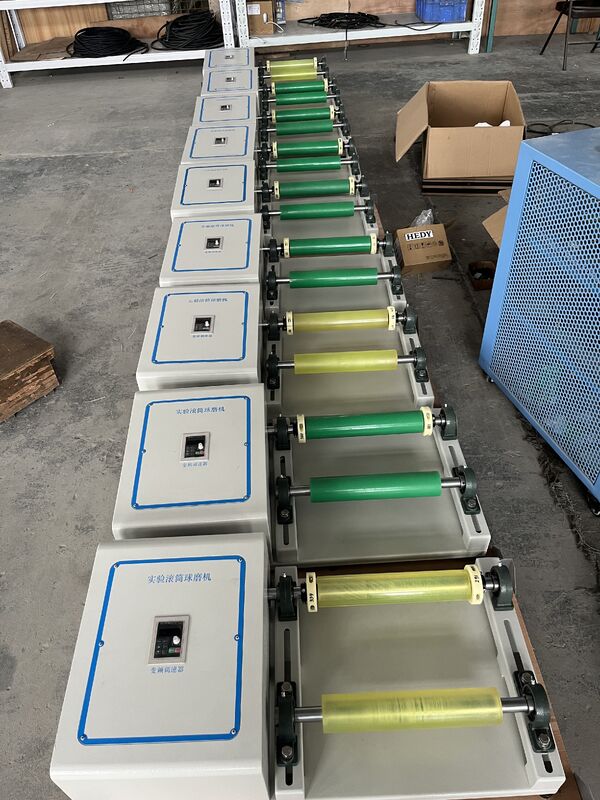

- Simultaneous grinding of multiple sample materials

- Intermittent and continuous operation modes

- Adjustable timing to suit specific requirements

Available Grinding Pots & Balls

Complete range of grinding jars available in various materials:

- Zirconia ball mill jar

- Alumina ball mill jar

- Agate ball mill jar

- Tungsten ball mill jar

- Hard metal mill jar

- And other specialized materials

Packaging & Shipping

Manufacturing Facility

Frequently Asked Questions

What roll mill jars are available in your products?

Our available roll mill jars include alumina/zirconia ceramic, nylon, stainless steel, tungsten carbide, PTFE, polyurethane, and more.

What are your terms of delivery?

FOB, CFR, CIF.

Can you accept small quantity sample orders before production?

Yes, we can provide samples for testing before production, with customers responsible for courier costs.

What is your production time?

Generally 3-15 days after receiving advance payment. Specific delivery time depends on items and order quantity.

What are your terms of payment?

T/T 30% as deposit, 70% balance against copy of original B/L, or 100% L/C at sight. We provide product photos and B/L copy before balance payment.

About KINGDA Ceramic Technology

- Specialized manufacturer of Grinding Media Balls, Grinding Jars, Zirconium Dioxide, and Zirconia structures

- "Quality Is in the First Position forever" - trusted by prestigious institutions including University of Oxford, Loughborough University, Peking University, and Tsinghua University

- Commitment to providing high quality grinding products and excellent customer service

- Established reputation for mutual benefit and sustainability with business partners

- Dedicated to technological advancement and customer satisfaction

Related Products

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!