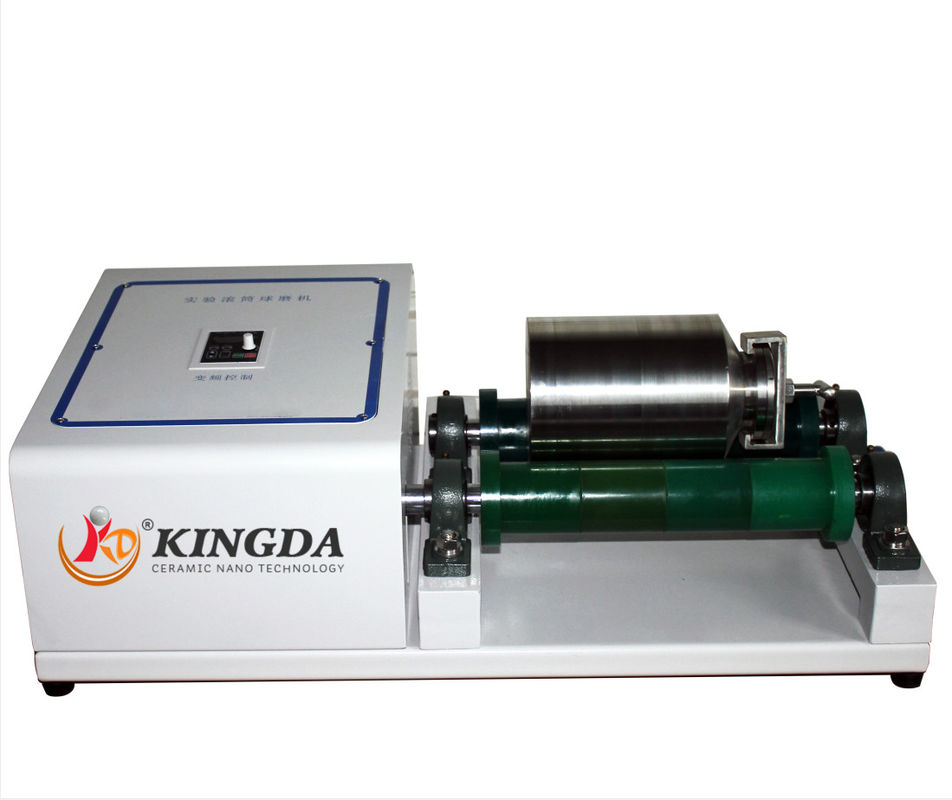

Kingda Lab Rolling Ball Mill

The Kingda Lab Rolling Ball Mill is advanced laboratory equipment designed for efficient sample preparation, grinding, blending, and homogenization processes. This versatile machine serves various scientific fields including materials science, pharmaceutical research, and chemical engineering.

Key Operational Features

- Adjustable rotation speed up to 570 rpm (roller speed, not mill jar speed)

- Compatible with various roll mill jar sizes with direct replacement capability

- User-adjustable settings for flexible installation and operation

The machine features a sturdy base housing a horizontal roller mechanism with multiple high-quality jars (stainless steel or ceramic) precisely aligned for stable and consistent milling. Researchers can customize milling parameters including rotational speed, jar size, and duration for optimal results.

Working Principle

During operation, grinding media and cylinder materials rotate to a predetermined height before descending from the tube wall under gravity. Material crushing occurs through impact, friction, and shearing from rolling and sliding motions, ensuring efficient operation with minimal time and labor.

Technical Specifications

| Category |

Model No. |

Power Supply |

Rotate Speed |

Max Load Per Jar |

Dimensions & Net Weight |

| 1 Work Position |

KD-QM-5 |

220V-50Hz or 110V single phase 0.37kw |

60-570 rpm |

35KGS |

730*415*260mm 32KGS |

| 1 Work Position |

KD-QM-15 |

220V-50Hz or 110V single phase 0.37kw |

60-570 rpm |

80KGS |

845*435*270mm 45KGS |

Product Features

- Simultaneous grinding of multiple sample materials

- Intermittent and continuous operation modes

- User-adjustable timing for customized requirements

Grinding Pots & Balls Accessories

Available Grinding Jars

Zirconia ball mill jar, alumina ball mill jar, tungsten ball mill, hard metal mill jar and more.

Material-Specific Jar Recommendations

| Materials & Requests |

Recommended Solutions |

| Soil materials and other materials not allowing impurity contamination |

Agate mill jar |

| Metal or nonmetal materials not allowing impurity contamination |

Zirconium mill jar |

| High hardness materials like diamond, tungsten carbide |

Tungsten carbide mill jar |

| Strong acid & alkali materials, or materials under high temperature |

PTFE mill jar |

| Iron ore materials or materials with low impurity sensitivity |

304 stainless steel mill jar |

| Pigment or materials with later processing under high temperature |

Nylon mill jar |

| Aluminum materials like ceramic glaze |

Corundum mill jar |

| Electronic materials like lithium battery |

Polyurethane mill jar |

Available Roll Mill Jar Specifications

| Description of Roll Mill Jars |

Available Specifications |

| Normal ceramic roll mill jar |

From 1.0L to 15L |

| 304 Stainless steel roll mill jar |

From 0.5L to 20L |

| Corundum roll mill jar |

From 0.5L to 10L |

| Nylon roll mill jar |

From 0.5L to 20L |

| Polyurethane roll mill jar |

From 0.5L to 20L |

| PTFE/Teflon roll mill jar |

From 0.5L to 20L |

| Tungsten carbide roll mill jar |

From 250ml to 3L |

| Roll jacket (Stainless steel) |

0.5L to 3L |

| 316l Stainless steel roll mill jar |

Customized |

Packaging & Shipping

Package Type: PE Form + Cartons / Wooden cases; Customizable according to customer requirements

Port: Shanghai Port, Guangzhou Port, Tianjin Port, Qingdao port

Delivery Time: Within 3-7 working days from payment receipt

Manufacturing Facility

Frequently Asked Questions

Q: What roll mill jars are available in your products?

A: Our available roll mill jars include alumina/zirconia ceramic, nylon, stainless steel, tungsten carbide, PTFE, polyurethane and more.

Q: What are your terms of delivery?

A: FOB, CFR, CIF.

Q: Can you accept small quantity sample orders before production?

A: Yes, we can provide samples for testing, with customers covering courier costs.

Q: What is your production time?

A: Generally 3-15 days after receiving advance payment, depending on items and order quantity.

Q: What are your payment terms?

A: T/T 30% deposit, 70% balance against B/L copy, or 100% L/C at sight.

Customer Service

- Custom grinding ball production according to your needs

- Comprehensive product testing before delivery

- Professional business relationships built on mutual respect

- Prompt response within 2 hours for all inquiries

About Kingda Ceramic Technology

HUNAN KINGDA CERAMIC TECHNOLOGY CO.,LTD specializes in manufacturing grinding media balls, grinding jars, zirconium dioxide, zirconia structures, and related products.

With "Quality Is in the First Position forever" as our guiding principle, we have earned high reputation and recognition from domestic and international customers including University of Oxford, Loughborough University, Peking University, and Tsinghua University.

We are committed to providing high-quality grinding products and exceptional services, contributing to mutual benefit and sustainability in the industry.

Related Products

Click on product images for detailed information:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!