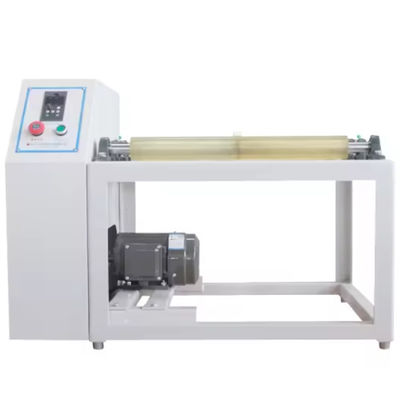

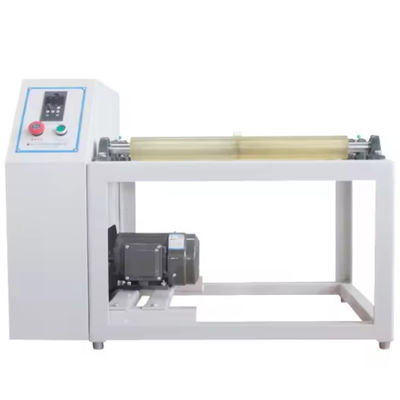

Kingda Lab Jar Mill /Roller Jar Mill Machine Roller Ball Mill/ Small Rolling Mill

Product Description————————

1. Pharmaceutical Mixing:

Achieve unparalleled precision in pharmaceutical mixing for optimal drug formulation utilizing our state-of-the-art GQM-1-5 Lab Jar Milling Machine. Additionally, streamline your lab processes with our optional integrated digital controls for enhanced efficiency.

2. Food Industry Homogenization:

Elevate the standards of uniformity in food production processes by harnessing the homogenization capabilities of our Lab Jar Milling Machine. Take advantage of our specialized attachments designed specifically for food industry applications to ensure consistent results with every batch.

3. Cosmetic Product Development:

From luxurious creams to silky lotions, revolutionize your cosmetic product development journey by achieving unparalleled texture and blend consistency with the cutting-edge technology of our Lab Jar Milling Machine. Explore our range of interchangeable jars and mixing blades tailored to meet the diverse needs of cosmetic formulation.

4. Paint and Coating Manufacturing:

Propel your paint and coating manufacturing endeavors to new heights of excellence with the precision milling prowess of our Lab Jar Milling Machine. Experience enhanced color dispersion and superior quality finishes through customizable milling parameters and advanced agitation options.

5. Ceramic Material Synthesis:

Unleash the potential of ceramic material synthesis in your research labs with the uniformity assurance provided by our Lab Jar Milling Machine. Complement your experimentation with our comprehensive selection of jar materials and sizes, optimized for precise control over particle size distribution and composition.

Working Principle————————

Upon commencement of operation, the grinding media and cylinder materials rotate to a predetermined height. Guided by gravity, they then descend from the tube wall.

Material crushing occurs through grinding media impact, along with friction and shearing from rolling and sliding.

This process not only saves time and labor but also guarantees ease of operation.

Specifications————————

| Category |

Model No. |

Power Supply |

Rotate Speed |

Max Load

Per Jar

|

Dimensions

& Net Weight

|

| 2 Work Positions |

GQM-2-5 |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*480*685mm 59KGS |

| |

GQM-2-15 |

220V-50Hz or 60Hz/1.1kw |

40-365 rpm |

80KGS |

1130*550*690mm 80KGS |

| |

GQM-2-20 |

220V-50Hz or 60Hz/1.5kw |

40-340 rpm |

120KGS |

1350*650*690mm 92KGS |

| 4 Work Positions |

GQM-4-5 Single layer |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*660*690mm 70KGS |

| |

GQM-4-5 Double layer |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*480*870mm 92KGS |

| |

GQM-4-15 |

220V-50Hz or 60Hz/1.5kw |

40-365 rpm |

80KGS |

1130*800*690mm 95KGS |

| |

GQM-4-20 |

380V-50Hz or 60Hz/2.2kw |

40-340 rpm |

120KGS |

1350*820*690mm 122KGS |

| 8 Work Positions |

GQM-8-5 |

220V-50Hz or 60Hz/1.5kw |

50-410 rpm |

35KGS |

950*660*960mm 106KGS |

| |

GQM-8-15 |

380V-50Hz or 60Hz/2.2kw |

40-365 rpm |

80KGS |

1130*800*960mm 152KGS |

Features————————

1.Multiple sample materials can be ground simultaneously.

2.It offers both intermittent and continuous operation modes.

3.Users can adjust timing to suit their requirements.

Accessories of Grinding Pots & Balls————————

Available grinding jars in full sizes:

Zirconia ball mill jar, alumina ball mill jar, Agate ball mill jar, Tungsten ball mill, hard metal mill jar and etc.

Package & Shipping————————

Package Type:

PE Form + Cartons / Woodern cases;

Can be dispatched according to customr's requirement

Port:

Shanghai Port, Guangzhou Port, Tianjin Port, Qingdao port.

Delivery time:

Within 3-7 working days from the date of payment receipt

FAQ————————

1.Q: What are the roll mill jars available in your products?

A: Our available roll mill jars are alumina / zirconia ceramic, nylon, stainless steel, tungsten carbide, PTFE, polyurethane and so on.

2.Q: What is your terms of delivery?

A: FOB, CFR, CIF.

3.Q: Can you accept small quantity sample order before production?

A: Yes, we can offer sample for your testing first before production, but the customers have to pay the courier cost.

4.Q: What is your production time?

A: Generally, it will take 3-15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

5.Q: What is your terms of payment?

A: T/T 30% as deposit, 70% balance against the copy of original B/L. Or 100% L/C at sight. We'll show you the photos of the products and the copy of original B/L before you pay the balance.

Our Service————————

1. We can produce other grinding balls as your need.

2. We test all the goods before delivery.

3. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

4. If you have any questions, please contact with us without any hesitation, we will reply you in 2 hours.

ABOUT KINGDA————————

1. HUNAN KINGDA CERAMIC TECHNOLOGY CO.,LTD is a manufacturer of the Grinding Media Ball, Grinding Jars, Zirconium Dioxide, Zirconia structures, etc.

2. "Quality Is in the First Position forever", we have gained a high reputation and good recognition from a lot of domestic and overseas customers such as University of Oxford, Lough borough University, Peking University, Tsinghua University, etc.

3. We promise that we would make great efforts to provide high quality grinding products and best services for all customers in the coming years.

4. Nowadays, KINGDA CERAMIC MATERIALS has gained great reputation from our business partners. We will continue to contribute the best to realize mutual benefit and sustainability.

5. We appreciate your interest and support in the efforts and passion of KINGDA CERAMIC, the company of Human Technology.

Related Products————————

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!