Kingda 0.72KW/220V Lab Roll Ball Mill for Ultra-Fine Grinding with 1000 Mesh Output

Rolling Jar Mill is a powder milling equipment designed for ultra-fine grinding and mixing in laboratory and small batch production environments. Also known as a roller ball mill, this machine features multiple working positions for efficient processing.

The Kingda Roll Ball Mill is the preferred equipment for scientific research, education, experimentation, and production due to its elegant design, compact structure, easy operation, high efficiency, and uniform granularity output.

This versatile machine is widely applied across various industries including electronic materials, magnetic materials, biological medicine, ceramic glaze, metal powder, nonmetallic minerals, and new materials development.

Featuring an optimal rotating speed design, the mill jar is dragged to rotate by rubber rollers while the balls inside create an incline flow movement to effectively disperse materials.

Working Principle

When the machine begins operation, the grinding media and materials within the cylinder are rotated to a specific height. Due to gravity, they fall downward from the tube wall. The materials are crushed through the impact action of the grinding media, combined with friction and shearing action from the grinding media's rolling and sliding motion. This efficient process saves time and labor while ensuring easy operation.

Specifications

| Category |

Model No. |

Power Supply |

Rotate Speed |

Max Load Per Jar |

Dimensions & Net Weight |

| 2 Work Positions |

GQM-2-5 |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*480*685mm 59KGS |

| GQM-2-15 |

220V-50Hz or 60Hz/1.1kw |

40-365 rpm |

80KGS |

1130*550*690mm 80KGS |

| GQM-2-20 |

220V-50Hz or 60Hz/1.5kw |

40-340 rpm |

120KGS |

1350*650*690mm 92KGS |

| 4 Work Positions |

GQM-4-5 Single layer |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*660*690mm 70KGS |

| GQM-4-5 Double layer |

220V-50Hz or 60Hz/0.75kw |

50-410 rpm |

35KGS |

950*480*870mm 92KGS |

| GQM-4-15 |

220V-50Hz or 60Hz/1.5kw |

40-365 rpm |

80KGS |

1130*800*690mm 95KGS |

| GQM-4-20 |

380V-50Hz or 60Hz/2.2kw |

40-340 rpm |

120KGS |

1350*820*690mm 122KGS |

| 8 Work Positions |

GQM-8-5 |

220V-50Hz or 60Hz/1.5kw |

50-410 rpm |

35KGS |

950*660*960mm 106KGS |

| GQM-8-15 |

380V-50Hz or 60Hz/2.2kw |

40-365 rpm |

80KGS |

1130*800*960mm 152KGS |

Key Features

- Multiple sample materials can be ground simultaneously

- Operates in both intermittent and continuous modes

- Customizable timing settings to meet user requirements

Grinding Pots & Balls Accessories

Available grinding jars in full sizes include:

Zirconia ball mill jar, alumina ball mill jar, Agate ball mill jar, Tungsten ball mill, hard metal mill jar and more.

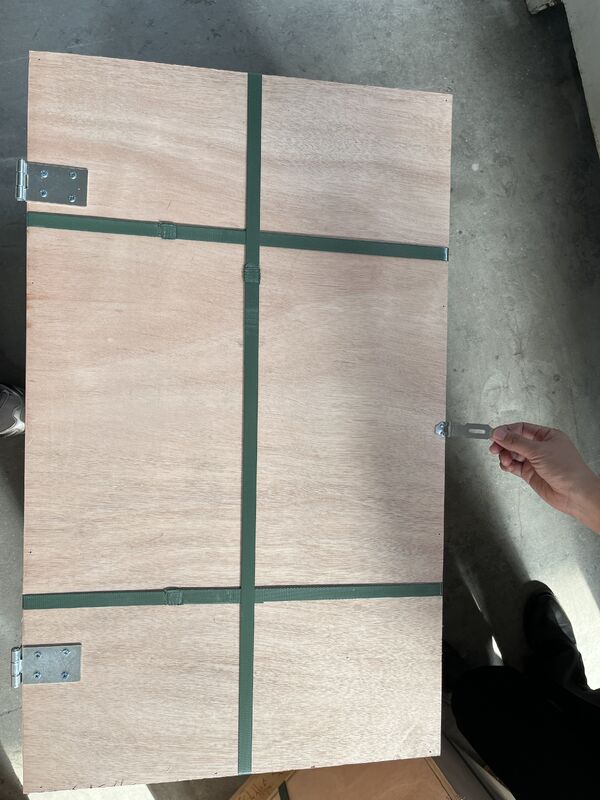

Package & Shipping

Package Type

PE Form + Cartons / Wooden cases; Can be dispatched according to customer requirements

Port

Shanghai Port, Guangzhou Port, Tianjin Port, Qingdao port

Delivery Time

Within 3-7 working days from the date of payment receipt

Factory Overview

Frequently Asked Questions

What roll mill jars are available in your products?

Our available roll mill jars include alumina / zirconia ceramic, nylon, stainless steel, tungsten carbide, PTFE, polyurethane and more.

What are your terms of delivery?

FOB, CFR, CIF

Can you accept small quantity sample orders before production?

Yes, we can offer samples for testing before production, with customers responsible for courier costs.

What is your production time?

Generally 3-15 days after receiving advance payment. Specific delivery time depends on items and order quantity.

What are your terms of payment?

T/T 30% as deposit, 70% balance against copy of original B/L, or 100% L/C at sight. We provide product photos and B/L copy before balance payment.

Our Service Commitment

- Custom grinding ball production according to your needs

- Comprehensive testing of all goods before delivery

- We treat every customer as our friend and value long-term business relationships

- Quick response - we reply to all inquiries within 2 hours

About Kingda Ceramic Technology

HUNAN KINGDA CERAMIC TECHNOLOGY CO.,LTD specializes in manufacturing Grinding Media Balls, Grinding Jars, Zirconium Dioxide, and Zirconia structures.

With "Quality Is in the First Position forever" as our motto, we have earned high reputation and recognition from domestic and international customers including University of Oxford, Loughborough University, Peking University, and Tsinghua University.

We are committed to providing high quality grinding products and exceptional services to all customers. Today, KINGDA CERAMIC MATERIALS enjoys great reputation among business partners, and we continue to contribute to mutual benefit and sustainability.

Related Products

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!